توضیحات

دانلود کتاب و حل المسائل (حل تمرین) مبانی ماشینکاری و ابزارهای ماشینی نوشته جفری بوثروید و وینستون ای. نایت – ویرایش سوم

این کتاب در چارت درسی گرایش ساخت و تولید کارشناسی مهندسی مکانیک و در مقطع کارشناسی ارشد قرار دارد.

عنوان های فصول کتاب:

- ابزارهای ماشینی و عملکرد ماشینکاری

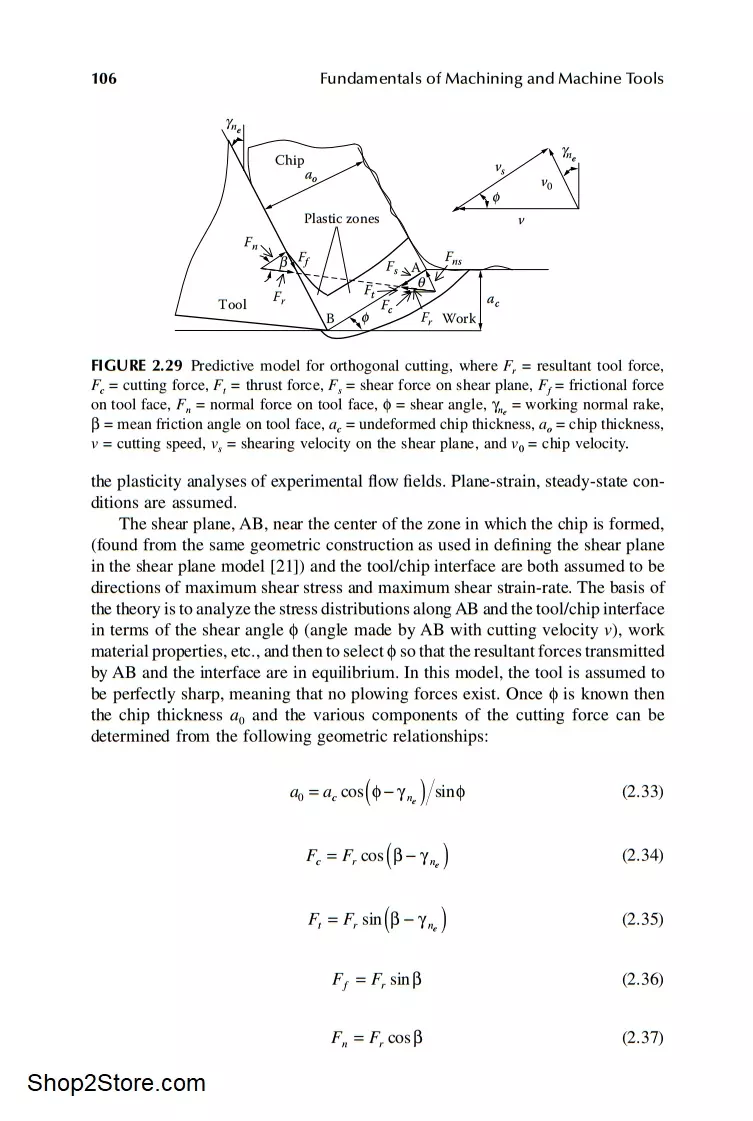

- مکانیک برش فلز

- دما در برش فلز

- عمر ابزار و مواد ابزار

- سیالات جهت برش و زبری سطح

- اقتصاد عملیاتی برش فلز

- نامگذاری ابزارهای برش

- کنترل چیپ

- ارتعاشات ابزار ماشینکاری

- سنگزنی

- سیستم های ساخت و اتوماسیون

- ساخت به کمک کامپیوتر (CAM)

- طراحی برای ماشین کاری

- فرایندهای ماشینکاری غیرسنتی

مقدمه کتاب مبانی ماشینکاری به زبان اصلی:

The history of metal cutting dates from the latter part of the eighteenth century. Before that time machine tools did not exist, and the following extract from the diary of an English engineer, Richard Reynolds, dated October 1760, gives some idea of the manufacturing problems that had to be faced.

Richard Reynolds was attempting to produce a cylinder for a tire engine for drawing water from a coal pit. The cylinder, of cast brass, had a length of 9 ft and a bore 28 in.

in diameter. He wrote: Having hewed two balks of a deal to a suitable shape for the cylinder to lie therein solidly on the earth in the yard, a plumber was procured to cast a lump of lead of about three hundred weight, which being cast in the cylinder, with a dike of plank and putty either side, did make it of a curve to suit the circumference, by which the scouring was much expedited.

Clarification

I then fashioned two iron bars to go around the lead, whereby ropes might be tied, by which the lead might be pulled to and fro by six sturdy and nimble men harnessed to each rope, and by smearing the cylinder with emery and train oil through which the lead was pulled, the circumference of the cylinder on which the lead lay was presently made of a superior smoothness:

after which the cylinder is turned a little, and that part made smooth, and so on, until with exquisite pains and much labor the whole circumference was scoured to such a degree of roundness as to make the longest way across less than the thickness of my little finger greater than the shortest way: which was a matter of much pleasure to me, as being the best that we so far had any knowledge of.

More info

In 1776 James Watt built the first successful steam engine, and one of his greatest difficulties in developing this machine was the boring of the cylinder casting. His first cylinder was manufactured from sheet metal, but it could not be made steam tight.

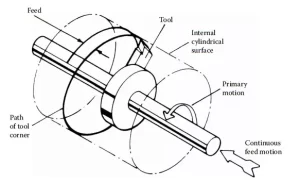

Even attempts to fill the gap between the piston and the cylinder with cloth, leather, or tallow were of no avail. John Wilkinson eventually solved the problem when he invented the horizontal-boring machine. This machine consisted of a cutting tool mounted on a boring bar that was supported on bearings outside the cylinder.

The boring bar could be rotated and fed through the cylinder. Thus generating, with the tool points, a cylindrical surface independent of the irregularities of the rough casting (Up Figure). This boring machine was the first effective machine tool, and it enabled James Watt to produce a successful steam engine.

Metal cutting, as we know it now, started with the introduction of this first machine tool. Today, machine tools form the basis of our industry and are used either directly or indirectly in the manufacture of all the products of modern

civilization.

در صورت داشتن هرگونه سوال و یا مشکل در بخش پشتیبانی شاپ تو استور مطرح نمایید.

اگر این محصول را خریداری کنید،

اگر این محصول را خریداری کنید،

دیدگاهها (0)

نقد و بررسیها

هنوز بررسیای ثبت نشده است.